The Tunerworks ServiceBMW S65 & S85 Rod Bearing Update |

| |

We have witnessed firsthand the connecting rod bearings are prone to premature wear, and in extreme cases, complete failure. This is due to the extremely tight rod bearing oil clearances.This is how we update them. |

There is no doubt the connecting rods take the most abuse out of any other components in the engine. The limits of engineered steel are continually put to the test with modern high revving engines. Manufacturers are pushing the boundaries of these components to meet the high demand of CAFE (Corporate Average Fuel Economy) standards.

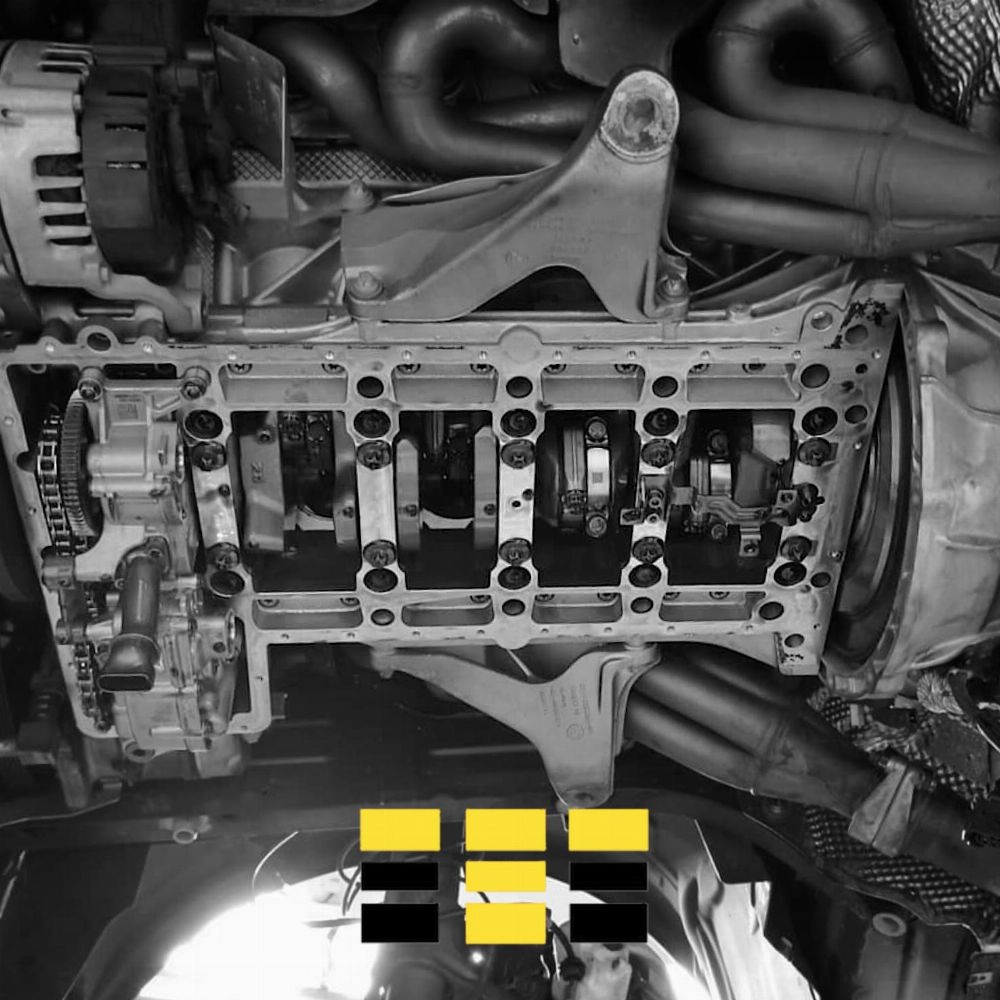

The BMW S65 V8 and S85 V10 engines were the pinnacle of engine technology of their time, these engines were featured in the BMW flagship M series cars. Engine technology included the fracture-split connecting rod. These connecting rods are forged as a single piece of metal, precisely scored along the big-end bearing and broken in half. This process leaves an uneven fractured surface of which makes up the connecting rod and big-end cap. This is thought to create a stronger bond between the rod and cap, however now eliminates the ability to service or resize the rod.

We have witnessed firsthand the connecting rod bearings are prone to premature wear, and in extreme cases, complete failure. This is due to the extremely tight rod bearing oil clearances. The lack of oil lubrication between the crank journal and particularly the upper rod bearing subjects the upper rod bearings to excessive wear. This wear is amplified when the use of high viscosity oil is used, such as the OEM recommended BMW 10w60 Motorsport oil. The remedy… to install updated rod bearings designed with a larger oil clearance. With this update, we also recommend the ARP connecting rod bolt kit. This service is recommended as a preventative measure. If the connecting rod bearing failure occurs the crankshaft and connecting rod are typically compromised and cannot be repaired without complete engine disassembly.

The process to replace the connecting rod bearings is as follows:

- Engine oil is drained

- Engine is supported from above with a specialized engine brace

- Front subframe is removed by disconnecting control arms, steering rack, and motor mounts

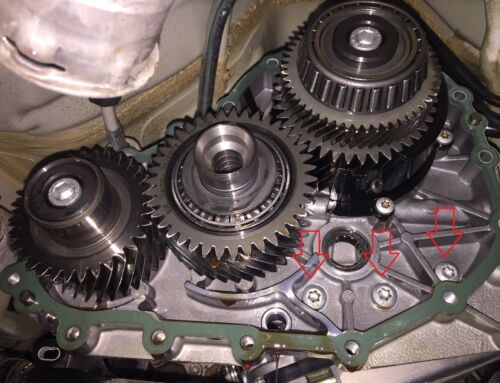

- Oil pan is removed and rod bearing end caps are exposed

- Once bearings are removed, the technician will inspect bearing surfaces to ensure no damage has occurred to the crankshaft or connecting rods

- New bearings are installed with recommended ARP connecting rod bolt set and bearing clearances are recorded to verify correct oil clearance

- Engine is filled with new factory spec oil

- Four wheel alignment is performed

- Vehicle is road tested to verify the repair

- Customer is recommended to return for an oil change within 1000 kms – engine oil can be sent out for analysis at this time

If you are in need, or have some questions for us, do not hesitate to be in touch right here.